Electric vs Gas Powertrain Comparison

- Flight Club Aerospace

- Jul 28, 2020

- 3 min read

According to a 2019 New York Times report, air travel currently accounts for 2.5% of global CO2 emissions, and those emissions are expected to triple by 2050. Decarbonizing aviation with electric aircraft powered by renewable energy therefore stands as viable mitigation to greenhouse gas emissions and the corresponding global warming. By building an electric ultralight airplane, we hope to gain a deeper understanding of the advantages and shortcomings of electric airplanes, and hopefully document it in sufficient detail for other aircraft enthusiasts to experiment with electric powertrains as well.

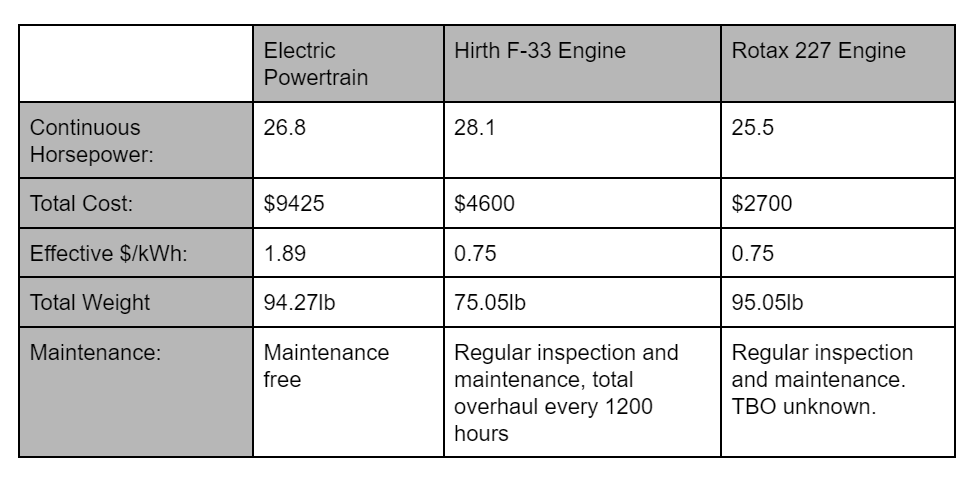

How does our electric powertrain compare to that of a typical reciprocating internal combustion engine? To answer this question, we first compared our motor and speed controller to the popular Hirth F-33 and Rotax 227 two-stroke reciprocating internal combustion engines. We then compared our lithium battery system to the standard 5 gallon limit of aviation fuel as defined in 14 CFR Part 103.

Powerplant comparison

As shown in the table above, the MGM Compro REB30 motor and HBC speed controller match or outperform both internal combustion engines in every category besides price. Most importantly, electric motors are mechanically much simpler than an internal combustion engine, which makes them cheaper and easier to operate and maintain. While an internal combustion engine may have tens of moving parts, our electric powerplant has only one. This eliminates issues such as carburetor icing, fuel pumping, and regular overhauls which can be costly and time consuming. Additionally, while internal combustion engines waste the majority of the energy stored in gasoline in the form of heat, our motor and speed controller have a combined efficiency greater than 80%.

Power source comparison

Despite recent advancements in lithium battery technology, gasoline is still the clear winner when it comes to power sources. To create an accurate and fair comparison, we recalculated the power density of aviation fuel and our battery pack to reflect the efficiency losses of the powerplant. Not taking maintenance costs into account, gasoline is 2.5 times cheaper than our lithium battery pack in terms of effective kWh. Avgas also has around 4.26 times the effective power density of our battery pack and is 2.54 times lighter per effective Wh. Note that in the calculations below we have excluded the 1.34lb battery management system (BMS) and the weight of a gas can. All values are approximations based on preliminary calculations but should be accurate within ±10%.

Total Powertrain Comparison

When all is taken into account, our electric powertrain only outperforms that of an internal combustion engine when it comes to maintenance and its simplicity. Though the motor and speed controller far outperform an internal combustion engine, lithium battery technology doesn’t have the necessary power density to make it a viable option in the long term. In addition, our electric powertrain costs more than twice that of even the higher end internal combustion powertrains making it economically impractical. In this way, our ultralight stands as a concept plane to demonstrate the future potential of electric aircraft once battery technology advances to become lighter, denser, and more affordable. This may seem far off at the moment but recent developments in solid state lithium batteries, hydrogen fuel cells, and alternative chemistries such as lithium air batteries may soon make electric aircraft a practical reality.

Battery Comparisons

For more information on how we went about designing our custom battery pack, check out our lithium battery comparisons spreadsheet. We compare the best battery cells (as of early 2020) based on real testing data to get estimates on weight, capacity, power density, and much more. The spreadsheet also includes a handy calculator which will automatically generate the detailed specifications of a battery pack based on your system voltage and continuous power requirement. We selected the Samsung 40T 21700 cell because of its relatively low cost per kWh, high discharge, and high power density. The Samsung 25R 18650 cell came in a close second with a proportionally higher discharge rate bua higher cost and slightly reduced power density. The higher proportional discharge rate reduces the minimum number of cells to meet a specific power requirement and creates a lighter battery at the expense of losing a little bit of capacity per kilogram and paying a bit more per kWh.

Comments